- Advanced Interconnect Technologies

- 2.5 & 3D Heterogeneous Integration

- System in Package (SiP)

- Wafer Bumping & WLP

- Multi-Chip Modules (MCMs)

- Novel Microfabrication & MEMS

- Design, Packaging & Assembly

- Assembly Services

- Final Test

- Chip on Board (CoB)

- Plastic Packaging (BGA/CSP/QFN)

- Hermetic Packaging

- MIL-STD-1553 Data Bus Couplers & Accessories

- Micro In-Line Couplers

- Tab Mounted In-Line Couplers

- Through Hole Mounted In-Line Couplers

- Box Couplers

- Custom Design Couplers

- Data Bus Coupling Transformers

- Data Bus Relays

- Data Bus Harnesses

- Bus and Stub Terminators

- Wide Bandwidth RF & Video Transformers

- Antenna Couplers

- Video Isolation Transformers

- RF Wideband Transformers

- RF Wideband Transformers & Impedance Adapters

Once devices have been packaged and tested, many customers choose to engage Micross to manage their inventories of finished products. Our ultra-clean inventory facilities meet JEDEC industry standards for temperature and humidity and are closely monitored for any change in ambient conditions. We have the capability to drop-ship product to customer to help manage inventories in the supply chain. Micross provides regular inventory reports showing accurate inventory status.

What's Included:

- Procurement of raw parts for a given set of products per customer forecast

- Holding and management of raw part inventory on consignment

- BOM monitoring to mitigate risk of EOL/PCN and to enable program/product lifecycle extension

- Modification/testing of parts per requirements on customer drawings

- Holding of finished goods inventory as needed

- Delivery to customer defined location in accordance with customer provided MRP or as otherwise directed by customer

- Invoicing when finished goods are shipped to customer

SMI Benefits:

- Free up cash and increase ROIC

- Convenience of one PO and "one source solution"

- Reduce administrative cost associated with multiple purchase orders, shipments, supplier interfaces, order status, material handling, expedites...

- Last time buys can be executed and inventoried at Micross facilities for an extended time period

- Diminished risk of non-compliant material being inadvertently assembled into the end product

- Reduced pricing for services & operational efficiencies attained by combining similar packages for production

- Parts can be kitted per material requirement planning (MRP)

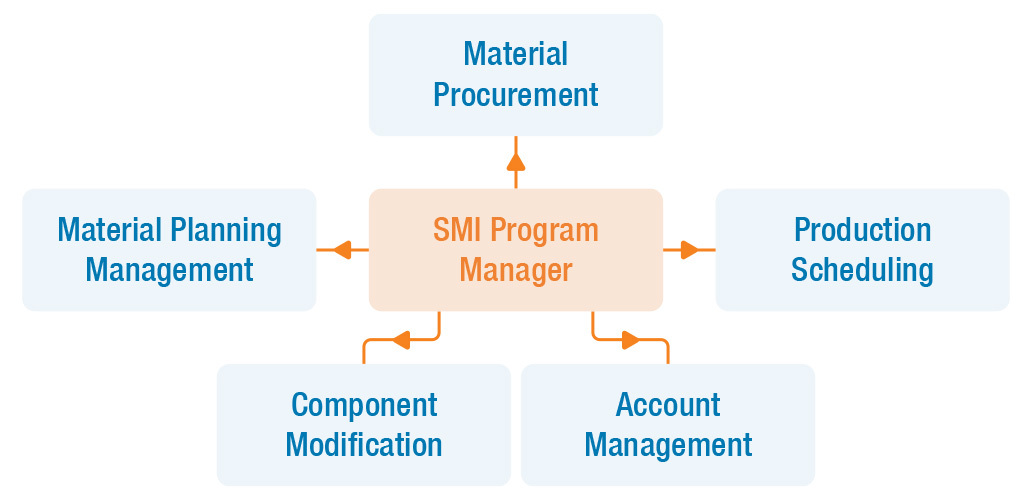

SMI - How we manage:

SMI Program Manager

- Single point of contact with overall responsibility for meeting customer requirements

SMI Program Manager Critical Functions

- Procurement (dedicated resource) – works with suppliers to procure parts at most competitive cost and ensure parts are available to meet customer requirements

- Materials Planning (PM or dedicated resource depending on volume) - customer interface to understand demand and delivery requirements and coordinate internally with procurement and production planning

- Production Scheduling

- Account Management

- Supported by dedicated incoming inspection & materials management resources

Experience

- Micross provides SMI and Turnkey solutions for 30+ customers

- Currently supporting more than 650 unique parts and program projected to double by year-end, with an annual volume of ~500k units

Note: Micross can also provided individual Turnkey Solutions enabling OEMs to outsource inventory procurement of parts requiring component modification.