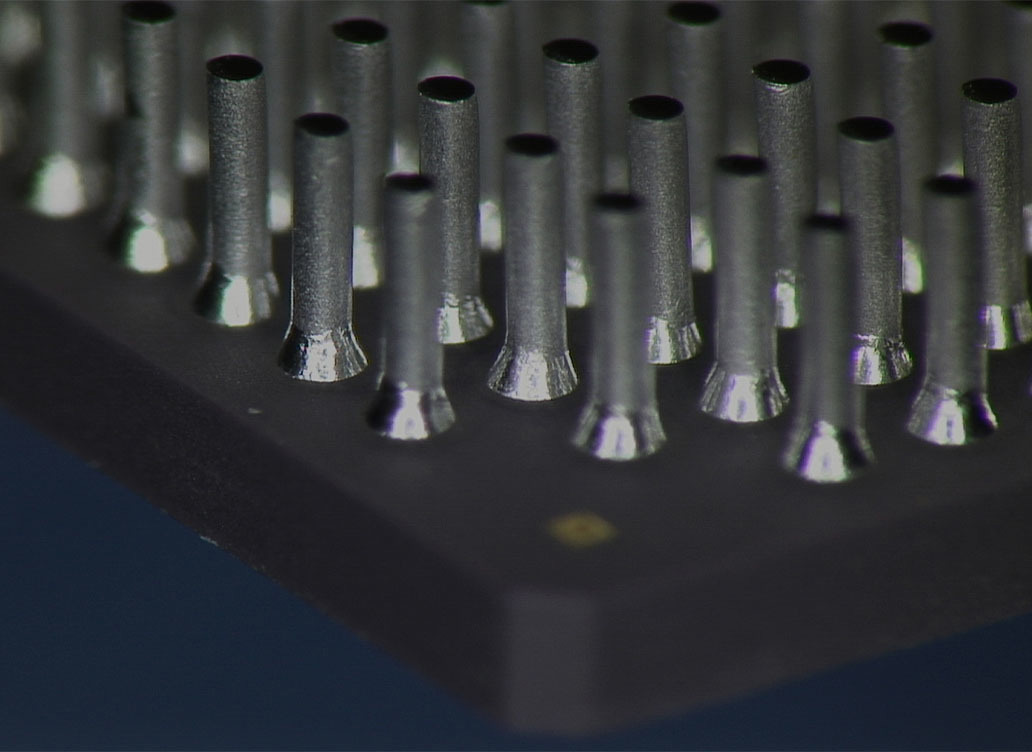

CGA is an enabling interconnect technology for high reliability applications, providing superior performance over BGA in thermal cycling by utilizing column interconnects to mitigate thermal stresses, where these stresses could shear standard BGA interconnects.

Micross provides a variety of Column Attach Services following identical processes, materials and workmanship standards as customers have been accustomed to historically from IBM.

- 10/90 Sn/Pb Columns

- Column Attach w/ Palladium Paste

- Precision Coplanarity & Pitch

- Post Column Attach Electrical Test (-55°C to +125°C)

- Proprietary Application Specific Burn-In (ACBI™)

- Complete Turnkey Solution (Column Attach & Test)

The sheer design and craftsmanship of the patented column attach process by Micross guarantees a superior hi-reliability interconnect and best suited for assembly & component attached integrity. Micross’ highly technical development team coupled with comprehensive electrical and thermal characterization capabilities, allow for seamless turnkey assembly and custom, build-to-suit packaging.

Micross CGA Advantages

- The Micross 2.21 Column Provides Superior Reliability with Mitigating Mechanical Fragility and Other Factors

- CGA Packaging with Taller Solder Columns Made of Flexible or Compliant High-Pb Solder

- Direct Drop Placement in Most Devices up to 2500 Interconnects

- Established Licensed IBM Process

- Ability to Process Both Ceramic & Plastic LGAs and BGAs with 1.00mm or 1.27mm Pitch

- Coplanarity Typically 150 Micron or Better

- Solder Deguilding Providing Mitigation of Gold Embrittlement

- Low Cost, Quick Turn Service