- Advanced Interconnect Technologies

- 2.5 & 3D Heterogeneous Integration

- System in Package (SiP)

- Wafer Bumping & WLP

- Multi-Chip Modules (MCMs)

- Novel Microfabrication & MEMS

- Design, Packaging & Assembly

- Assembly Services

- Final Test

- Chip on Board (CoB)

- Plastic Packaging (BGA/CSP/QFN)

- Hermetic Packaging

- MIL-STD-1553 Data Bus Couplers & Accessories

- Micro In-Line Couplers

- Tab Mounted In-Line Couplers

- Through Hole Mounted In-Line Couplers

- Box Couplers

- Custom Design Couplers

- Data Bus Coupling Transformers

- Data Bus Relays

- Data Bus Harnesses

- Bus and Stub Terminators

- Wide Bandwidth RF & Video Transformers

- Antenna Couplers

- Video Isolation Transformers

- RF Wideband Transformers

- RF Wideband Transformers & Impedance Adapters

Need Component Validation Services?

Micross’ Premier Counterfeit Mitigation test lab performs screening of components in accordance with defined government & industry standards. As an independent third-party lab, Micross is a clear choice to help complete your BOM with known good parts when failure is not an option and every second counts!

Rest Assured with Micross

DLA Certified

Micross’ Premier Counterfeit Mitigation Services, is a quality-driven, independent, ITAR-Registered counterfeit mitigation lab that performs screening of customer-supplied components, and is certified to ISO/IEC 17025:2017, AS6171, and AS6081. For 20+ years our testing services have enabled an elevated level of assurance for contractors providing electronic components to the DoD. Micross is a wholly owned Independent Test House (from source of supply) with facilities in North America and Europe.

Industry Leading Turn Around Time

Complete Portfolio of Counterfeit Mitigation Testing Services

Documentation

Documentation

- Package

- Labels

Physical

Physical

- Orientation

- Leads or Spheres

- Marking

- Size, Weight, and Shape

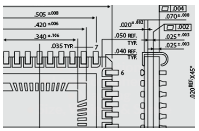

.png) Internals (Non-Destructive)

Internals (Non-Destructive)

- X-Ray

- Die, Shape, and Size

- Lead Frame

- Bond Wires

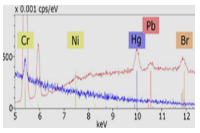

Composition

Composition

- Correct Metals

- Lead/Lead-Free

Marking

Marking

- Resistance to Solvents

- 3:1 Spirits/Alcohol

- Acetone

- Heated Solvents

- Dynasolve

- Scraping

.png) Internal Destructive

Internal Destructive

- Decapsulation

- Die Markings

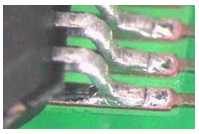

Solderability

Solderability

- Leads Free of Contaminants and/or Corrosion

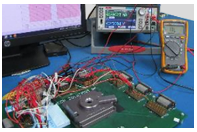

Electrical Performance

Electrical Performance

- Confirm Operation

Qualified to the Highest Standards

Micross inspects the component and packaging using the IDEA 1010 methodology and checklist to identify non-conformances on the IC body, leads and markings. High powered inspection equipment and experienced highly trained lab technicians, combined with Micross’ Counterfeit Database are all factors ensuring that any external issues are identified and documented.

Certifications

- AS9100D/ISO9001:2015

- ITAR Registered

- ANSI/ESD S20.20:2021

- CCAP-101

- ISO/IEC 17025:2017 - AS6171

- DLA Certified AS6081: A1, A3, A4, A5, A6

- FSC 5962 Limited Electrical Test per QTSL-5961 / 5962 3.1.3

- MIL-STD-750 - Test Methods (3001, 3011, 3036, 3041, 3061, 3066, 3071, 3076, 3406, 3407, 3411, 3413, 4001, 4011, 4016, 4021, 4022, 4023)

- Flows:

- Customer specific, Source Control Drawing (SCD) Raytheon, L3Harris, NGC, etc.

- ITAR Process

- JEDEC Standards