- Advanced Interconnect Technologies

- 2.5 & 3D Heterogeneous Integration

- System in Package (SiP)

- Wafer Bumping & WLP

- Multi-Chip Modules (MCMs)

- Novel Microfabrication & MEMS

- Design, Packaging & Assembly

- Assembly Services

- Final Test

- Chip on Board (CoB)

- Plastic Packaging (BGA/CSP/QFN)

- Hermetic Packaging

- MIL-STD-1553 Data Bus Couplers & Accessories

- Micro In-Line Couplers

- Tab Mounted In-Line Couplers

- Through Hole Mounted In-Line Couplers

- Box Couplers

- Custom Design Couplers

- Data Bus Coupling Transformers

- Data Bus Relays

- Data Bus Harnesses

- Bus and Stub Terminators

- Wide Bandwidth RF & Video Transformers

- Antenna Couplers

- Video Isolation Transformers

- RF Wideband Transformers

- RF Wideband Transformers & Impedance Adapters

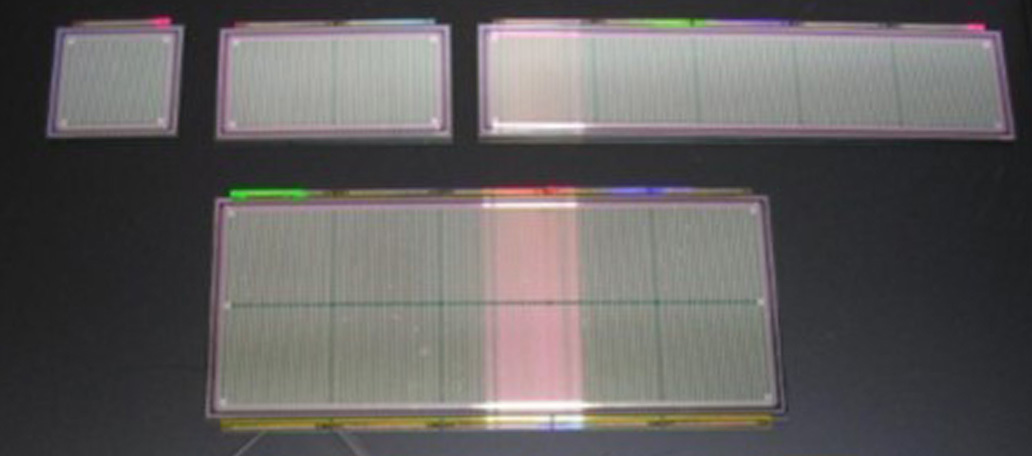

Flip Chip and Multi-Chip Module Assembly

Micross AIT offers a wide array of flip chip assembly capabilities, from single chip placements to multi-chip module and system-in-package assembly of multiple die and components.

- Flip chip assembly for single and multi-chip applications

- Precision die placement with accuracies better than +/- 0.5 microns

- Heterogeneous integration with Si, III-V and other device types/materials

- Plasma Assisted Dry Soldering (PADS) Process enables true fluxless for assembly for Sn-bearing solders

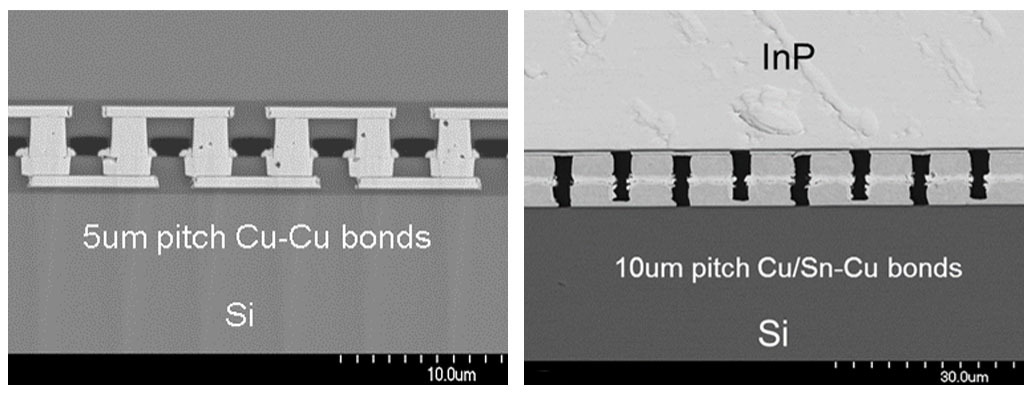

Metal-Metal Bonding for 2.5/3D Technologies

2.5D and 3D integration technologies are driving the integration of devices with extremely high interconnect densities for Si interposer and chip stacking applications.

- Solid/liquid interdiffusion assembly with CuSn-Cu bump arrays demonstrated down to 10 micron pitch

- Cu/Cu thermocompression bump bonding demonstrated down to 5 micron pitch

- Solutions for chip stacking and high thermal stability interconnects that remain solid at high temperatures