- Advanced Interconnect Technologies

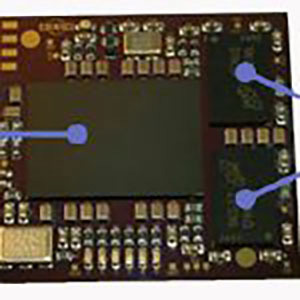

- 2.5 & 3D Heterogeneous Integration

- System in Package (SiP)

- Wafer Bumping & WLP

- Multi-Chip Modules (MCMs)

- Novel Microfabrication & MEMS

- Design, Packaging & Assembly

- Assembly Services

- Final Test

- Chip on Board (CoB)

- Plastic Packaging (BGA/CSP/QFN)

- Hermetic Packaging

- MIL-STD-1553 Data Bus Couplers & Accessories

- Micro In-Line Couplers

- Tab Mounted In-Line Couplers

- Through Hole Mounted In-Line Couplers

- Box Couplers

- Custom Design Couplers

- Data Bus Coupling Transformers

- Data Bus Relays

- Data Bus Harnesses

- Bus and Stub Terminators

- Wide Bandwidth RF & Video Transformers

- Antenna Couplers

- Video Isolation Transformers

- RF Wideband Transformers

- RF Wideband Transformers & Impedance Adapters

Micross AIT works with a wide variety of clients and partners, bringing integrated process, design, testing and analysis capabilities to projects involving custom application-driven development.

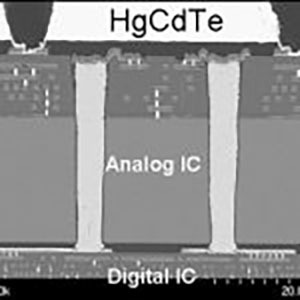

Micross AIT offers access to our 2.5D/3D technology platform through joint development projects, prototyping services and small volume production. Our 2.5D/3D integration technology platform is based on several enabling process modules, which include:

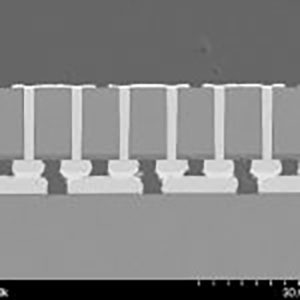

- Through-silicon via (TSV) interconnects

- High density 3D IC applications, filled 2-10 μm diameter, up to 8:1 aspect ratio and 10-50 μm pitch

- Lower density 2.5D/3D package architectures, 10-50 μm diameter, aspect ratio of 4:1 to 6:1 and 50-500 μm pitch; vias can be filled or barrel coated

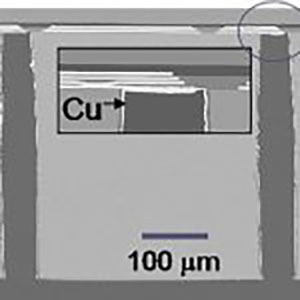

- Wafer thinning (to < 20 μm Si thickness) and processing on temporary carrier wafer

- Flip-chip and high-density metal-metal bonding, down to <10 μm pitch

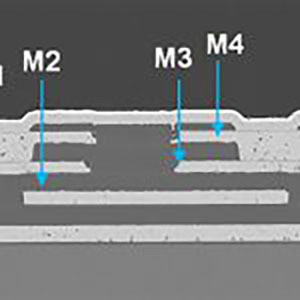

- Large-area multi-level metal routing with standard RDL (down to 10 μm L/S) or dual damascene process (down to 6 μm L/S)